Safety Arrangements

Lazer Safe – Performance Without Compromise

CLASS 1M single point laser transmitter

Safety class up to CAT.4 and SIL3

Protection class IP65

System response time of 5MS.

Single sensor photoreceiver

Velocity changeover points down to 5MM

Protection distance up to 15mm

LED indicators to show various statusOperating temperature

DSP Laser Safety System For Press Brake

The protection area of safety device for press brake is fixed under the cutting edge and moves synchronously with the upper slider,to ensure any object must enter the protection area before touching the cutting edge when the press brakes approach in high-speed.Once an obstruction (such as worker’s finger) enters the protection area, DSP will immediately make signal and interrupt the slider downward movement , which can protect the operator personal safety.

Advantage:

- The safety level is CAT.4 and SlL3

- Detection Case protection degree:lP 65

- Laser classification:class 1 M

- MCS Response time:2 ms

- Operating temperature 0°C-50°C

- Mounted on the upper beam

- Box Mode Function

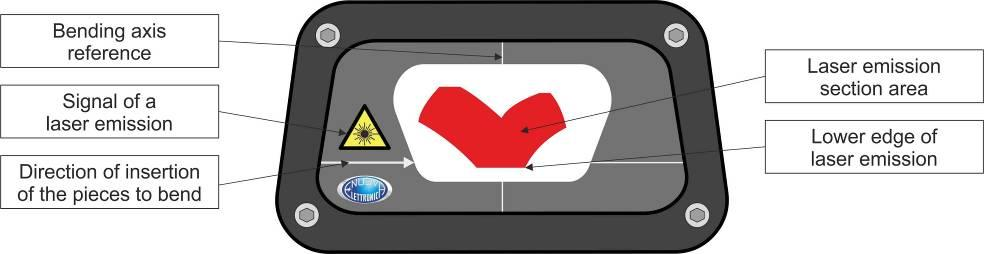

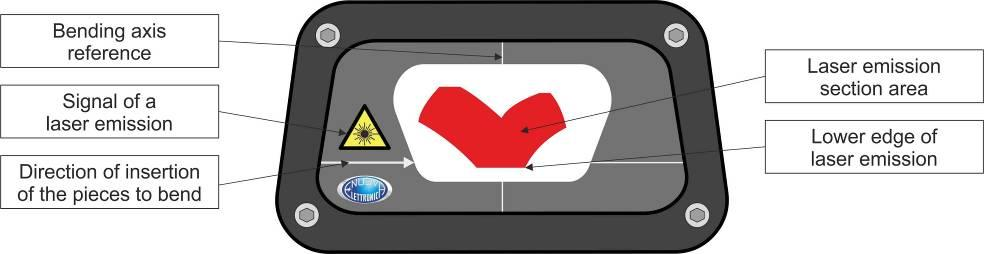

Diagram And Functions

MSD Laser Safety System For Press Brake

The photoelectrical safety device MSD is a single beam barrier with emission of visible laser which, within a more general control system, contributes to the protection of the operator in the use of machinery including dangerous mobile parts controlled by electric or electro-mechanical devices. Main task of MSD is to detect, within the limits defined by the device detection capability, the intrusion of any opaque physical elements inside the area defined as “detection area”, which is defined by the point of the emission of the laser beam generated by the transmitter up to the point of reception of the receiver of this device. The tool has been designed to disconnect, in case of danger, the power supply of the machine control devices and/or to activate functions which stop the motion of the dangerous parts.

Advantage:

- Laser protection,single beam Receiver- The safety level is CAT.4 and SIL3

- Detection case protection degree: IP65- Laser classification: class 1 M

- Response time: 5 ms

- Operating temperature 0°C~50°℃- Mounted on the lower beam

- Change speed point : 5mm

- The maximum protective distance : 15M-LED indicators show various states

Diagram And Functions

LAZERSAFE Laser Safety System For Press Brake

CNC press brake use OEM EMBEDDED LAZERSAFE offers a highly effective solution for both operator safety and machine productivity. Designed for use with Lazer Safe’s PCSS A Service, the Lazersafe is category 4 compliant and meets the world’s most demanding international safety standards(CE Certified Category 4 Safety Controller with integrated).

Advantage:

- CLASS 1 Dual Block laser

- Fast response time

- Safety speed automatically monitored

- Stopping distance automatically monitored

- Status LEDs – Power / Front/middle/rear Sensors

- Tray mode for high speed bending of tray & box shapes

- Complex shapes can be achieved in high speed with Tray/Box Mode.

Sensor Arrangemen

The laser field is processed by the receiver and divided into three continuous zones to detect obstructions entering from the front, sides and rear of the tool area. The front zone provides protection forward of the tool while the middle zone protects the area just behind the tip of the punch. The rear zone provides additional protection for the open gaps created when segmented tooling is used. The protective zones are independently and automatically muted to suit different shaped work pieces allowing parts to be formed safely at high speed to achieve maximum productivity.

Press Brake Control Safety System – Advanced

The PCSS-A is a programmable safety controller designed to improve the performance and safety of press brakes. It provides flexibility for the press brake manufacturer and simplifies the design process by combining all related control, safety and monitoring functions into a single system and eliminates the need for complex integration of third party components and software. PCSS-A provides an optimum balance of functionality and performance with reduced build cost.