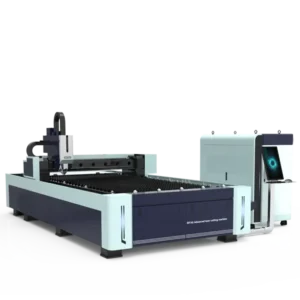

LISTEN Electric Shearing Machine

Simple Electric Shearing Machine For Sheet Shearing

electric shearing machine is overall steel-welded structure. This machine is used to cut 3 mm -6mm thick sheet metal with chain drive under the principle of guillotine shearing. There is no power consumption when not shearing because the motor has its own brake. The cutting width of the sheet can be adjusted with back gauge.

Material pressing device

Equipped with high compression and wear resistant polyurethane pressure feet, the board is pressed down with the knife holder during cutting to fix the board and prevent errors in board movement.

Feeding ball

The design of adding feeding balls to the front pallet provides support for the shearing plate while ensuring flexibility in feeding and preventing scratching of the plate.

Electrical cabinet

The electrical components are from well-known brands with stable performance, and the voltage can be customized according to customer needs.

Foot switch

The foot switch controls the cutting process, which is simple and easy to operate. It moves as you step on it, and does not cut or consume electricity without stepping on the foot switch. It is energy-saving and efficient.

Backgauge

Standard manual adjustment rear positioning device, suitable for customers to cut fixed size plates, while providing manual and electric rear positioning for customers to choose from.

Motor and reducer

The motor and reducer are directly connected to prevent power loss and ensure more efficient shearing.

Welding Technology

Selected steel, welded as a whole, with a reasonable structure

Selected high-quality high-strength steel plates are welded together as a whole, and the frame plate is thickened. The structural design is reasonable, and the body is stable and durable.

Blade Technology

High quality material selection, repeated forging, and high-temperature quenching

The blade is made of selected high alloy tool steel, which is forged by high-temperature quenching. It has high hardness, good wear resistance, and long service life. Both the upper and lower blades are designed with four sided cutting edges, which can be flipped over for use.

Copper Core Motor

Copper core coil, high-precision rotor, precision bearing

Copper core coil motor, with high power, strong power, stable output, durability, and no burning.

MD11 System

Numerical control system, powerful functions, simple operation

The MD11-1 CNC system is an 8-bit digital display with a user-friendly interface that is intuitive and easy to operate; The ultra large capacity can hold up to 10 programs, with strong anti-interference ability and built-in counting function. Each program can count up to 1000 times, and can be programmed in one go. The machine is controlled by foot pedals and runs independently

BackGauge System

Easy and convenient adjustment, efficient positioning, precise positioning

The system has a unique reverse function to prevent material collision and ensure long-term accuracy. It has a built-in soft limit function to directly protect the rear material and prevent overtravel. The system can adjust real-time parameter settings according to different mechanical tooth distances, with a repeated positioning accuracy of 0.1mm. The MD11 system belongs to the simple single axis series and must control the deceleration motor to ensure positioning efficiency